The Challenges of Starting an In-House Quality Department

Starting an in-house quality inspection department for a manufacturing company, or any other business, for that matter, can be a daunting and complicated task with no clear starting point. Whether you are looking to address quality issues with current production methods, analyze the adherence of parts to exacting specifications, or create repeatable procedures that meet industry standards, an in-house quality inspection department can make a considerable difference. However, in some instances, it is more beneficial to outsource quality inspection procedures to trusted experts like Geometric Design and Technology with decades of combined experience providing the foremost comprehensive solutions for geometric dimensioning and tolerancing quality control.

Initial Challenges for Starting an In-House Quality Department

Starting an in-house quality department, even for established manufacturing companies, can present a considerable set of challenges. Thankfully, GD&T can seamlessly step in and address these challenges with a diverse set of services and solutions designed to remove the stress of attempting an in-house quality control department and ultimately produce higher quality products at greater efficiency.

Determine Quality & Inspection Needs

No matter the industry, from die-casting to injection molding or precision CNC machining, delivering consistent quality across all parts or components is paramount to success in an increasingly competitive world. While it may seem simple to determine the exact quality and inspection needs, understanding how to properly measure and document these dimensional requirements is far more difficult. GD&T Inc. understands the intricate needs of each of these industries and can immediately determine the essential inspection needs that directly correlate to consistent product quality.

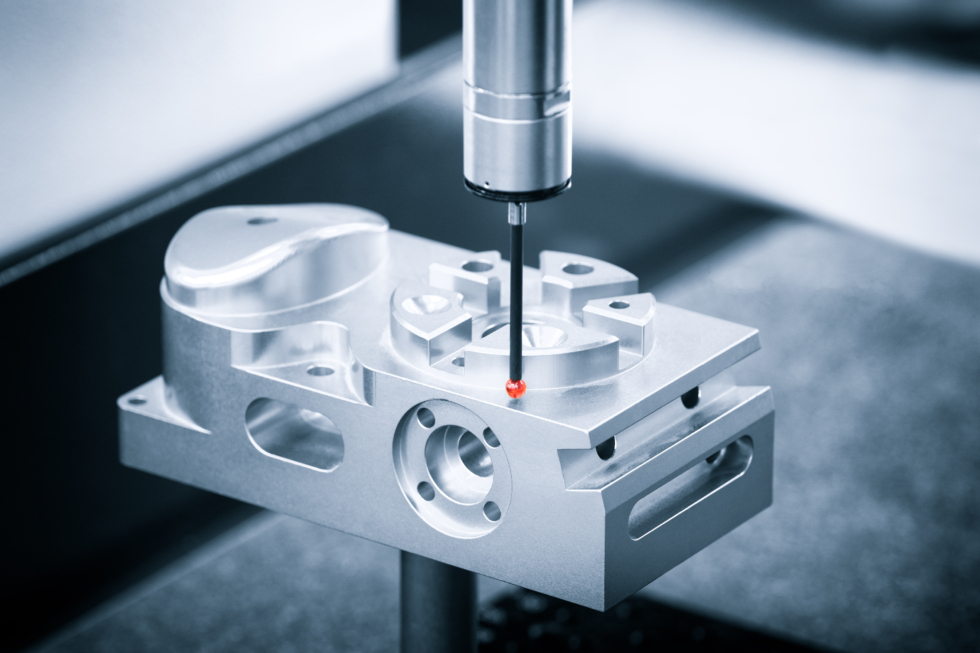

Space & Equipment

In-house quality inspection departments require dedicated space within your facility and a bevy of state-of-the-art, sensitive inspection equipment. Depending on the industry, a dedicated clean room may be required for detailed inspection services – another costly investment. Instead of worrying about finding space, buying the correct equipment, or learning how to operate said equipment, manufacturers can reach out to GD&T, who already have the established space and equipment to replace the services of an in-house quality inspection department.

Develop Inspection Procedures

Developing proper inspection procedures varies greatly from part to part and between industries. Whether that means adhering to recognized industry standards for quality like AS9100, fabricating dedicated fixtures to hold parts for inspection, or understanding the correct ways to utilize inspection equipment to capture the desired measurements, developing these procedures can be difficult for inexperienced companies. GD&T can help develop these inspection procedures and even provide turnkey solutions to customers who can then follow a detailed protocol and achieve the same results.

Documentation Practices

Documentation practices are essential to maintaining quality management standards like ISO or AS9100 and tracking manufacturing from the arrival of raw materials to final product quality as it leaves the facility. Mistakes happen, but following the established documentation procedures outlined by GD&T during their consultation or review process ensures these mistakes are minimal and do not impact existing quality management certifications.

Training & Continuous Improvements

Quality inspection departments aren’t a “set it and forget it” division for any business, and require ongoing training, continuous process and equipment improvement to remain ahead of industry trends and specifications. Rather than worrying about hiring trained professionals to run your in-house quality inspection department, GD&T already has the requisite training to provide the dimensional inspection and geometric tolerancing services you need to be successful.

Inspection Services Offered by GD&T

Geometric Design and Technology is a full-service provider of comprehensive quality solutions for any manufacturing sector or project requiring exhaustive quality control procedures. We are an A2LA ISO/IEC 17025:2017 accredited laboratory with the necessary world-class dimensional inspection equipment to capture precise measurements of large or uniquely shaped parts or machines. Our competitively priced, quality solutions address the many challenges faced by emerging manufacturing companies looking to avoid the challenges and pitfalls of starting an in-house quality inspection department. These services include:

- First Article Inspections

- Custom Fixtures & Gauges

- Manufacturing Quality Consulting

- Dimensional Inspection Services

- Part Sorting & Containment

- Dimensional Metrology

- On-Site Inspection & Metrology

- Turnkey Inspection Projects

- PPAP Services

- Large Scale Metrology

- Reverse Engineering

- Laser Scanning

Get A Quote

Outsourcing the operations of an in-house quality inspection department to experienced providers like Geometric Design and Technology can alleviate the expensive overhead of equipment, staff, and space involved. From determining inspection needs and developing proper procedures to handling documentation, equipment, and ongoing improvements, GD&T offers custom-tailored solutions that improve inspection efficiency, reduce costs, and ensure adherence to industry standards. With a wide range of services, cutting-edge technology, and a commitment to precision, GD&T provides the expertise manufacturers need to meet their quality goals and maintain a competitive edge in today’s fast-paced industries.